|

Product Details:

|

| Modulus Of Rupture: | 1.5MPa | Working Temperature: | 1450℃ |

|---|---|---|---|

| Compressive Strength: | ≥50MPa | Raw Material: | Bauxite |

| Permanent Linear Change: | 1400℃*3h±0.5 | Thermal Conductivity: | ≤1.5W/m·K |

| Refractoriness: | 1770-1790℃ | Usage: | Liner |

| Weight Of Brick: | 3-4KG/Pices | Shape Tolerance: | ±1mm |

| Porosity: | ≤22% | Ash: | 0.3% |

| Work Temperature: | 1400C | Application: | Kiln Lining |

| Iron Content: | ≤2.0% | ||

| Highlight: | Aluminum Fire Bricks SK34,Refractory High Alumina Brick,Rotary Kiln High Alumina Brick |

||

High Alumina Refractory Bricks

High alumina bricks refer to aluminosilicate refractory products with aluminum oxide (Al2O3) content higher than 48%. It belongs to neutral refractory material. It is formed by shaping and calcining bauxite or other raw materials with high alumina content. High thermal stability and fire resistance above 1770 ℃. It has good slag resistance and is used for lining steel making electric furnace, glass furnace, cement rotary furnace, etc.

High load soft and low creep high alumina brick is a high-grade refractory material made of special grade bauxite, fused corundum and fused mullite. The product has the advantages of small high-temperature creep, strong corrosion resistance, good thermal shock stability, etc. It is suitable for large and medium-sized hot blast furnaces.

High Alumina Refractory Bricks Advantage

1. High refractoriness;

2. High temperature strength;

3. High thermal stability;

4. Neutral refractory;

5. Good resistance to acid and basic slag corrosion;

6. High refractoriness under load;

7. High temperature creep resistance;

8. Low apparent porosity;

High Alumina Refractory Bricks Application

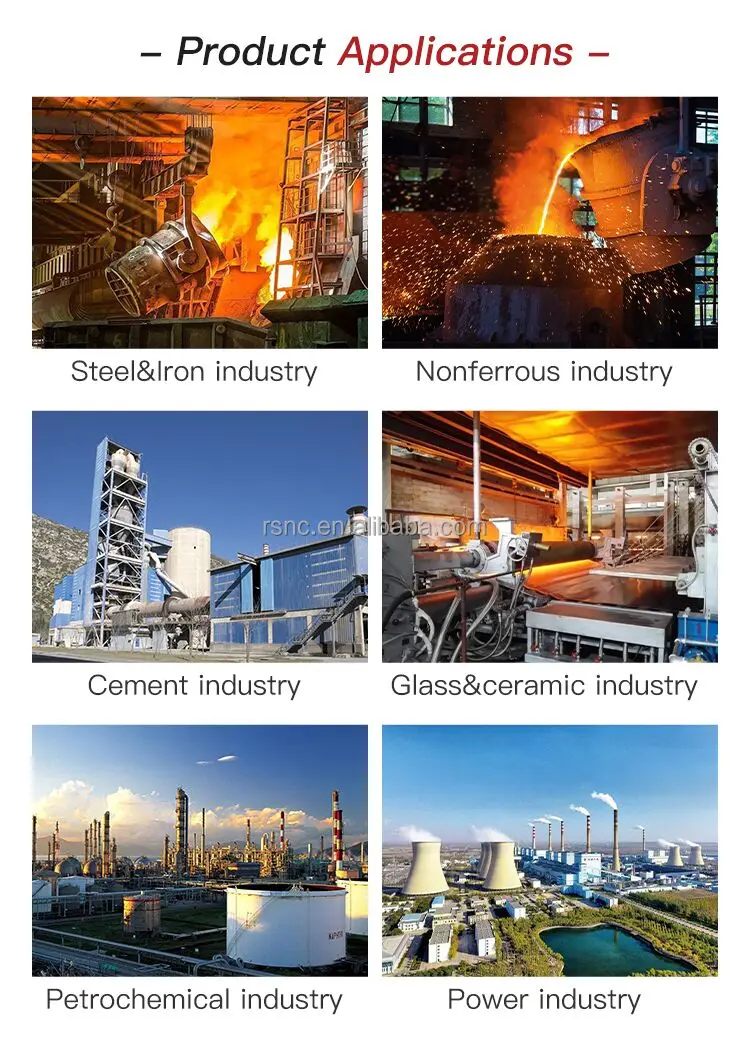

As a basic material in the field of high-temperature technology, high alumina bricks are widely used in cement, glass building materials, steel smelting, petrochemical and other industries. High temperature industrial furnaces for high alumina bricks include blast furnace, hot blast furnace, electric furnace, blast furnace, reverberatory furnace and rotary kiln lining. In addition, high alumina bricks can also be processed into open hearth regenerative grid bricks, socket bricks for pouring system, nozzle bricks, etc. according to the requirements of industrial furnaces.

Contact Person: Mr. Pika

Tel: 86-13838387996

Fax: 86-0371-56010932