| Water Addition: | 5-7% | Refractoriness: | 1770°< Refractoriness< 2000° |

|---|---|---|---|

| Apparent Porosity: | ≤18% | Product: | Corundum Castable |

| Size: | 0-3mm,Customizable | Application: | Furnace Lining |

| Corrosion Resistance: | Excellent | Maximum Service Temperature: | 1800°C |

| Purpose: | Keeping Heat And Promoting Efficiency | Raw Materials: | Bauxite Particle |

| Thermal Conductivity: | 2.5 W/mK | Bending Strength Mpa: | 8~20 |

| Compressive Streng: | 55.8MPa | Sample: | Freely |

| Advantage: | High Thermal Stability | ||

| Highlight: | High Temperature Kilns Ramming Mass,Medium Frequency Furnace Ramming Mass,Zirconium Based Ramming Mass |

||

Refractory Ramming Mass is an unshaped refractory material which is prepared by ramming (manual or mechanical) method and hardened by heating at a higher temperature.Ramming materials into acid, neutral, alkaline three

Refractory Ramming Mass uses high-quality high-alumina, corundum and spinel, fused and high purity magnesite as the main raw materials, add a variety of different binding agents and special properties of the fine powder materials, such as by the fine ratio and mixing made.

Features

1.On the face in contact with liquid metal there is a dense sintered layer where tightness of liquid metal is quite perfect.

2.Thermal conductivity is lower than other refractoriness so the Thermal loses are less than any other kind of refractory.

3.Good resistance to temperature change.

4.Low cost in furnace lining.

5.Short heating and sintering time through dry preparation Of masses.

6. Strong resistance to erosion.

Specification

Aluminum-magnesia ramming material, high-alumina (or corundum) – silicon carbide – carbon ramming material, alkali refractory ramming material and zirconium mullite ramming material.

Applications

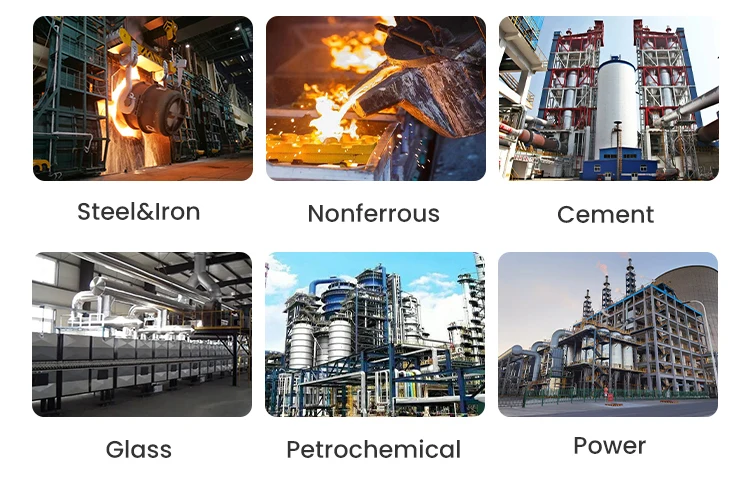

Ramming Mass mainly used for furnace lining of boiler, blast furnace, hot blast stove, heating furnace, ceramic kiln and various industrial furnaces.Applicable to all kinds of carbon steel, low manganese steel, alloy steel, alloy cast iron, high-speed tool steel and stainless steel.

Ramming Mass Physical and chemical index

Contact Person: Mr. Pika

Tel: 86-13838387996

Fax: 86-0371-56010932