|

Product Details:

|

| Refractoriness: | ≥1790℃ | Application: | High Temperature Industrial Furnaces |

|---|---|---|---|

| Extended Kiln Life: | Yes | Impact Resistance: | High |

| Softening Point: | High | Sample: | Free |

| Chemical Composition: | Al2O3-SiO2-CaO | Corrosion Resistance: | High |

| Working Temperature: | High | Linear Change Rate: | ≤0.2% |

| Alkali Resistance: | Excellent | Application Temperature: | 1400-1700℃ |

| Shape Type: | Standard Straight Shape | Porosity: | ≤20% |

| Iron Content: | ≤2.0% | ||

| Highlight: | High Temperature Kiln Refractory Bricks,High Quality Kiln Refractory Bricks,Furnace Kiln Refractory Bricks |

||

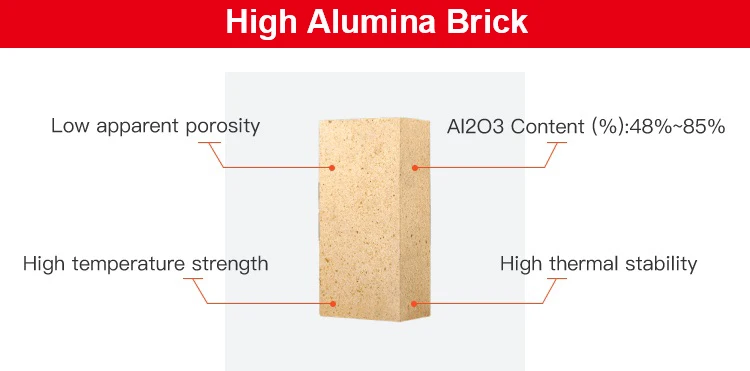

Introduction to high alumina refractory bricks

High alumina brick is a neutral refractory material with an alumina content of more than 48%. It is formed and calcined from bauxite or other raw materials with high alumina content. High thermal stability, fire resistance temperature above 1770℃.

Our high alumina brick raw materials

Our company only sources high-quality raw materials from long-term, trustworthy suppliers. All raw materials entering the factory are strictly inspected. Each production process will be strictly controlled to ensure quality and consistency to provide customers with the highest quality high alumina bricks.

Physical and Chemical Indicators For High Aluminum Brick :

| Item/Grade | Fire clay brick | High alumina brick | ||||||

| SK-30 | SK-32 | SK-34 | SK-35 | SK-36 | SK-37 | SK-38 | SK-40 | |

| AL2O3% (≥) | 30 | 35 | 38 | 45 | 55 | 65 | 70 | 82 |

| Fe2O3% (≤) | 2.5 | 2.5 | 2 | 2 | 2 | 2 | 2 | 2 |

| Refractoriness(SK) | 30 | 32 | 34 | 35 | 36 | 37 | 38 | 40 |

| Refractoriness under load, 0.2MPa, °C (≥) |

1250 | 1300 | 1360 | 1420 | 1450 | 1480 | 1530 | 1600 |

| Apparent porosity (%) | 22-26 | 20-24 | 20-22 | 18-20 | 20-23 | 20-23 | 20-22 | 18-20 |

| Bulk density (g/cm³) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 | 2.25-2.4 | 2.3-2.5 | 2.4-2.6 | 2.5-2.7 |

| Cold crushing strength MPa (≥) |

20 | 25 | 30 | 40 | 45 | 50 | 60 | 70 |

As a basic material in the field of high-temperature technology, high alumina bricks are widely used in cement, glass building materials, steel smelting, petrochemical and other industries.

High temperature industrial furnaces for high alumina bricks include blast furnace, hot blast furnace, electric furnace, blast furnace, reverberatory furnace and rotary kiln lining. In addition, high alumina bricks can also be processed into open hearth regenerative grid bricks, socket bricks for pouring system, nozzle bricks, etc. according to the requirements of industrial furnaces.

Contact Person: Mr. Pika

Tel: 86-13838387996

Fax: 86-0371-56010932